Applied Technology

‧Clinching panel fastener is mainly applied to precision work parts such as threads, screws, assembling parts etc. allowing time effective, economical and artistic to products. We make use of quick-clinching method and use bolts, screws and nuts to achieve tasks.

‧Technical Introduction as below:

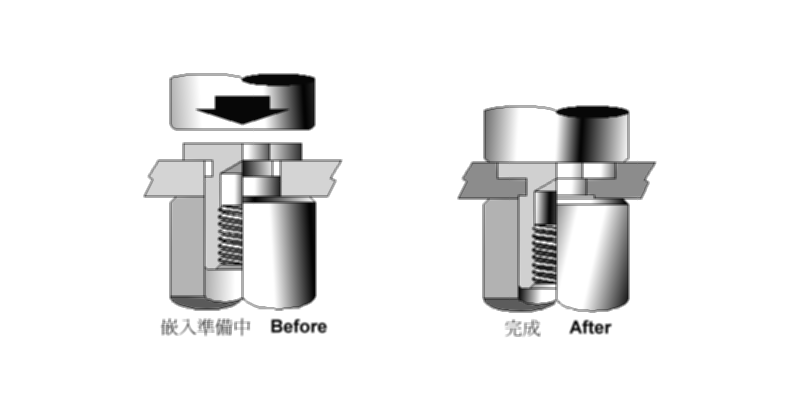

Nuts

1. Use punching-head (press m/c or hydraulic press) that suitable for pressure specification and suitable lower-mould. No needs to trim sheet's aperture (from drilling, punching or laser beam machining).

2. Place nut on sheet at the Clinching aperture.

3. As punching-head is parallel to lower-mould, exert pressure until nut's head is clinched and closely clipped with the sheet.

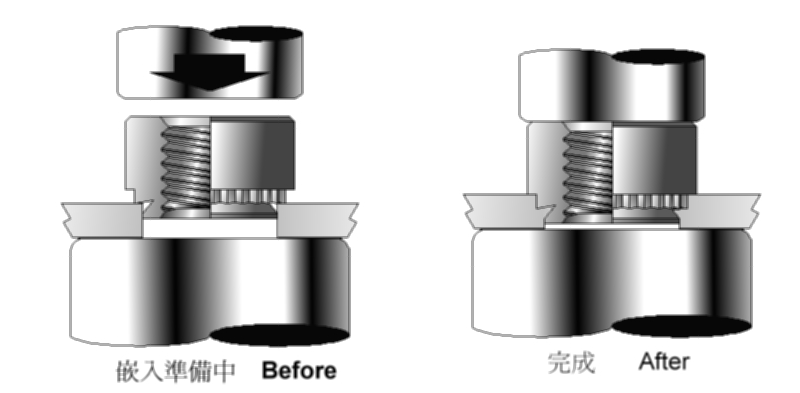

Bolts

1.Sheet needs to use required dimension for pressing or drilling.

2.Use punching-head and lower-mould that match with bolt's thread-diameter. Punching force is to be exerted on the head of the bolt and on the sheet, pressing bolt into sheet, allowing sheet to compress vicinity of bolt's head.

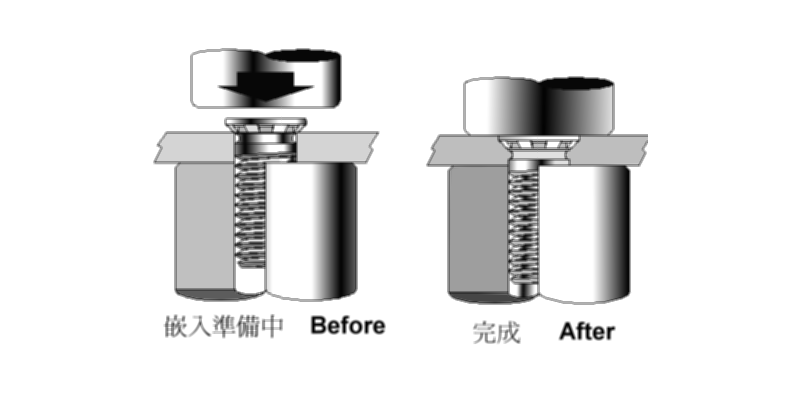

Standoffs

1. Make suitable apertures either by punching or drilling on the sheet. No need to remove deckle-edge or trim.

2. Place nut on the sheet and anvil as the figure.

3. Punching head needs to parallel to anvil. Use sufficient pressure to clinch nut into sheet.